Brief:

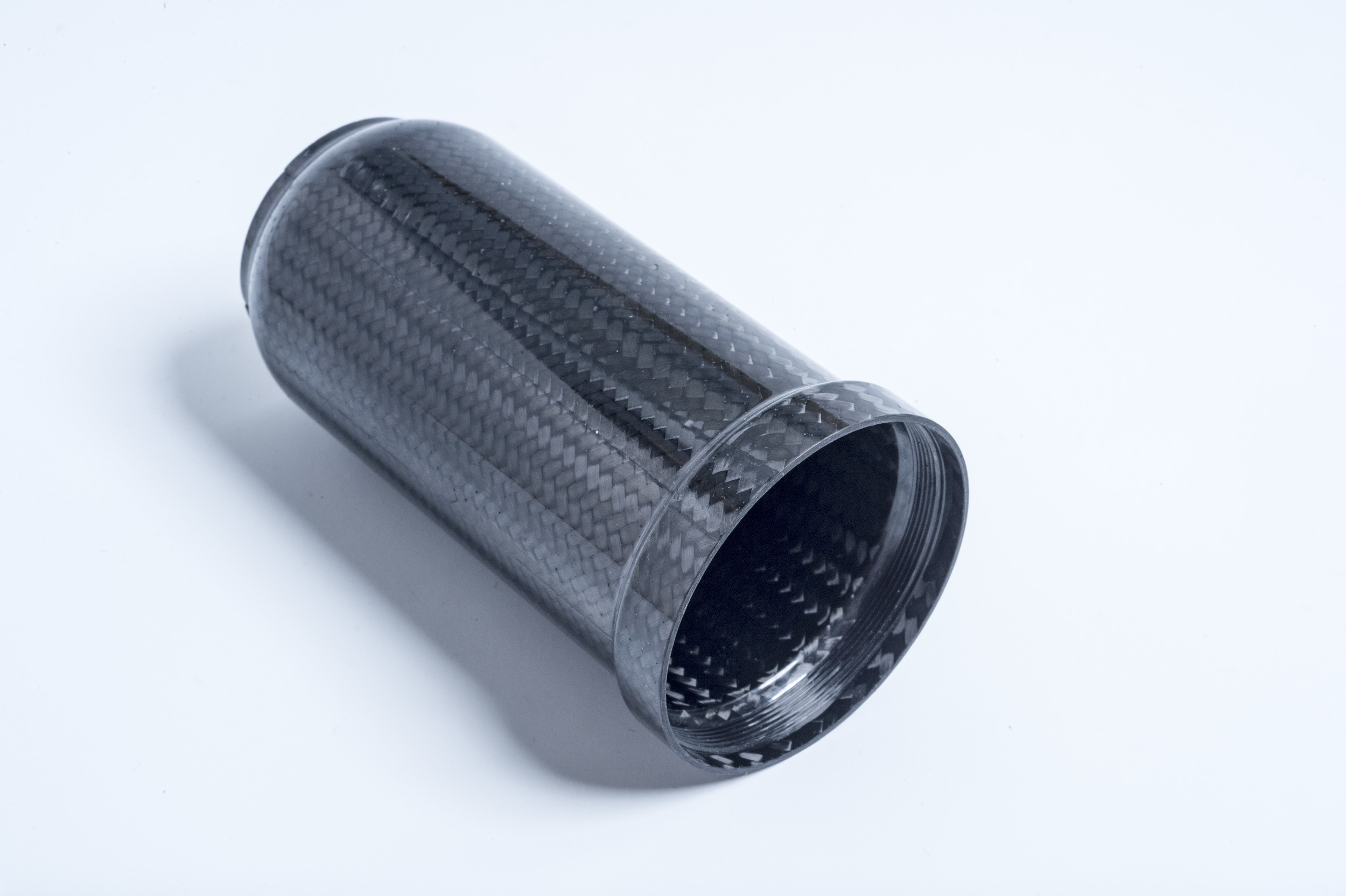

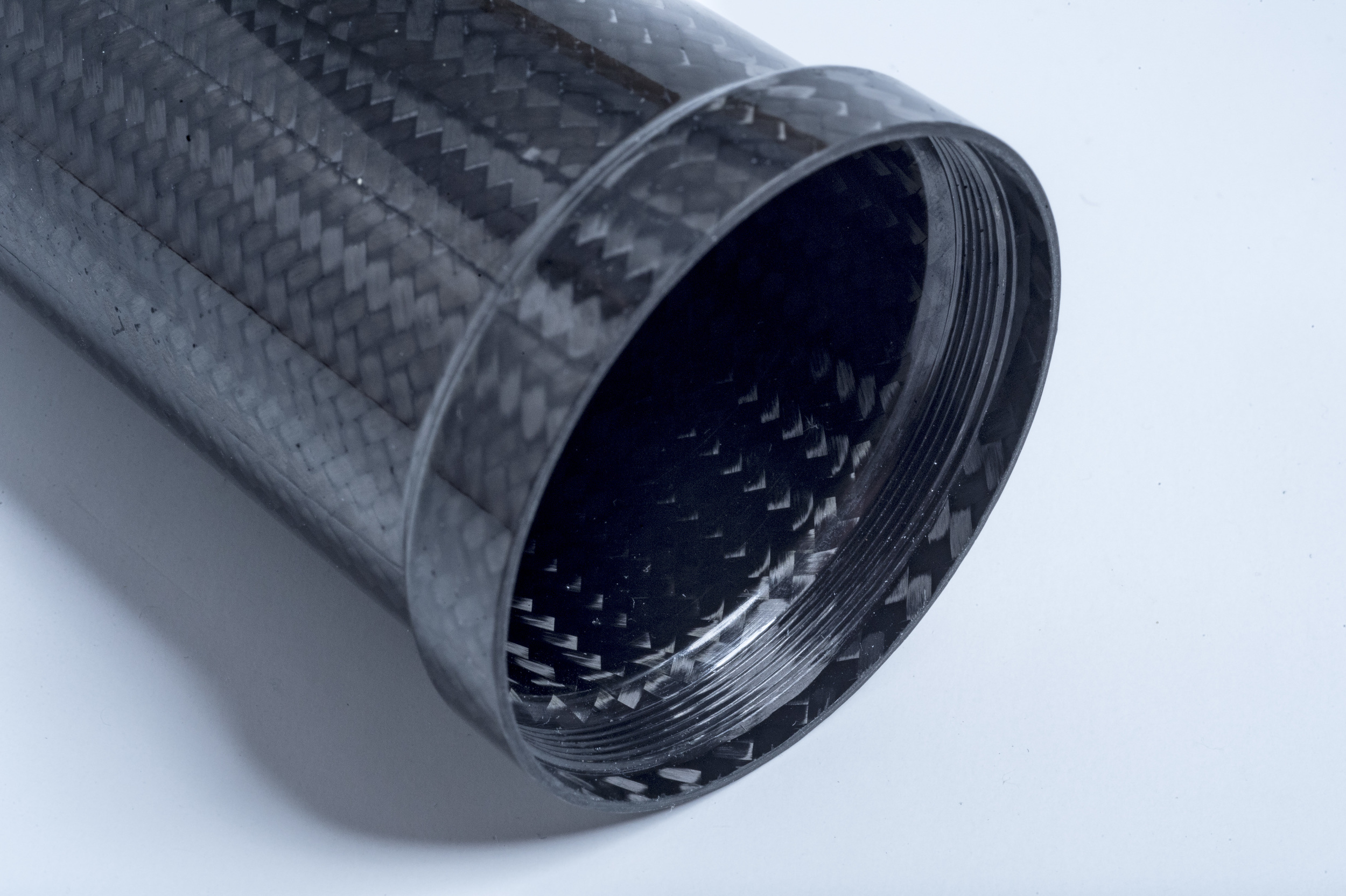

replace the standard aluminum air chamber housing by an entirely carbon version

Challenge:

- make class A surfaces on the inside (guiding and sealing) and outside (esthetics)

- make thread out of the same material

- deal with low heat dissipation of the carbon material

Result:

- Weight reduction of about 60% relative to the previous component: from 43g to18g (165mm eye-to-eye)

- lightest serial production air chamber worldwide

< back